Home > How we assure the quality

We are devoted to follow the ISO quality manu, what we setup. We have solid procedures to follow, thus the inter-deparments: Sales-Sample room – Purchasing – Production – IQC – QA are all clearly following the regular steps to archieve the goals.

We have strict stages:

a) Preparation before production

b) Production stage

c) Quality control

First of all, interdepartmental meeting will have solid information flow to the production colleagues for some points of the product need special attention, i.e. construction, sewing method...etc.

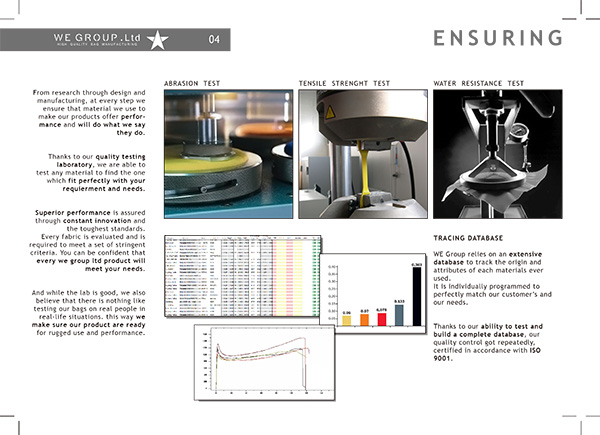

Materials would be ordered as product required, on the other hand, every incoming materials will be inspected under AQL by different fabric testing machine, from traction of fabric to the strength of buckles. In past years, we spent over USD 150,000 on testing facilities, part of testing details shown below:

2nd Production stage:

Weekly production report for situation is a must. On the other hand, the Quality Control inspectors in each workfloor will check at first 10 pcs in each step, before continuing to next stages until the work is acceptable. Moreover, A daily report will be given to factory manager.

3rd stage Product testing:

Quality final checking before packaging, we will have testing machine for testing strength of seams, plus a bag roller machine for the abrasive/durability of the fabric plus shoulder strap testing machines for the connecting points of messenger bags and backpacks.